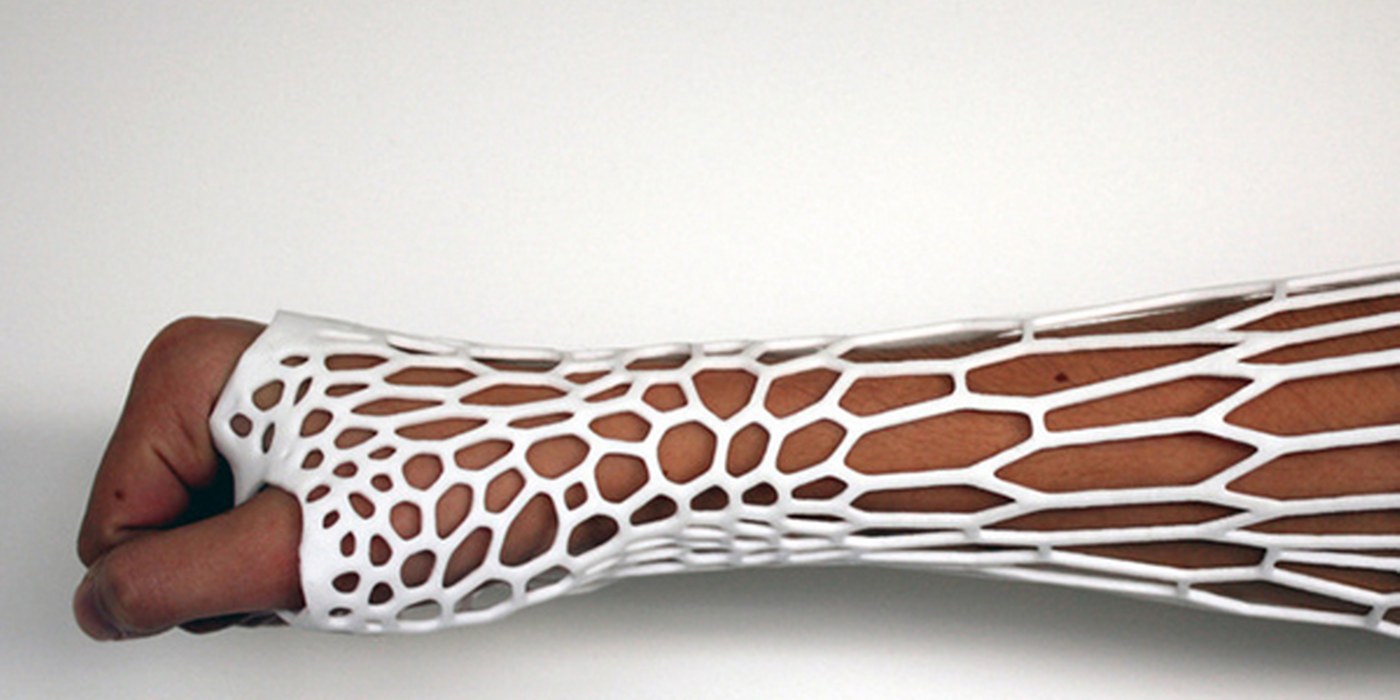

The goal of this project is to improve the overall healing experience for broken or fractured limbs by focusing on the patient’s comfort and the amount of time needed for the body to heal itself. Comfort; creating a stable and protective environment. Conventional medical casts sacrifice ventilation for structural integrity. As a result they are itchy, they smell very bad and due to plaster’s material properties they are bulky, heavy and they limit patient’s exposure to water. Osteoid medical cast offers a new way of tackling these problems by introducing new technologies which enables us to make custom fitted, durable 3d printed medical casts that doesn’t itch or smell. Plus due to material properties the end products are slimmer, lighter, doesn’t affect from water and environmentally friendly. Time; Osteoid medical cast can also be combined with its complimentary, low intensity pulsed ultrasound (LIPUS) bone stimulator system. For single 20 minute daily sessions this system promises to reduce the healing process up to 38% and increase the heal rate up to 80% in non-union fractures. In order to function, the LIPUS ultrasound probes has to be placed on the injured area with direct skin contact, because of this requirement it was not possible to use this method with patients using standard medical casts. Now thanks to the ventilation holes on the Osteoid medical cast the LIPUS bone stimulator probes can be placed over the injured area.

The LIPUS pulse generator has an on /off button at its side. At the center of this pulse generator there is a color switching led which guides the user about operational state and session time with different colors and blinking patterns.

The most difficult part was to come up with a fully functioning locking mechanism which is strong enough to protect the limb, practical enough to put it on the fragile injured area and simple enough so that it doesn’t disturb the general form of the medical cast.

via A’Design Award & Competition